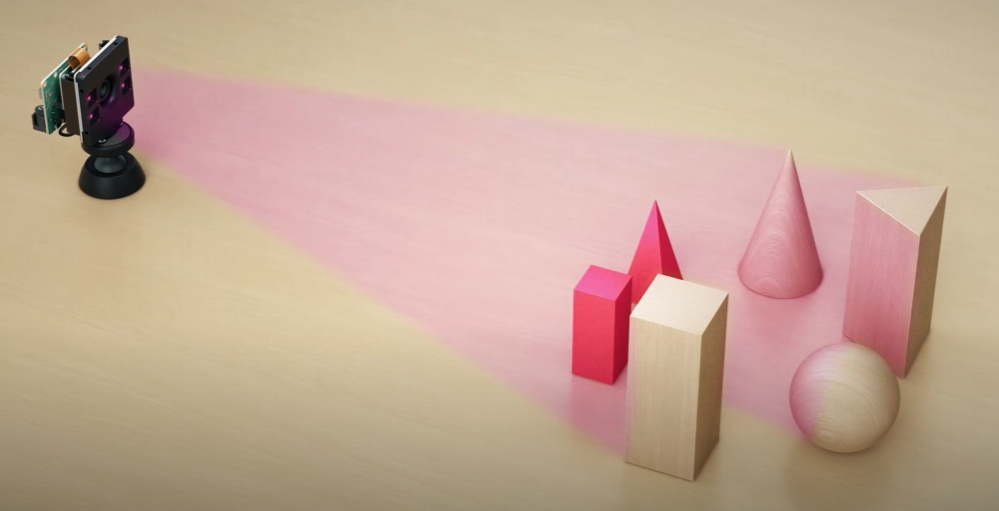

3D Time-of-Flight (ToF) sensors have become increasingly essential in fields requiring depth sensing, spatial mapping, and object recognition. These sensors measure the distance between themselves and objects using the time it takes for a light pulse to travel to the object and return. With advancements in sensor technology, ToF sensors have gained prominence not only in consumer electronics but also in industrial applications and advanced fields like robotics, artificial intelligence (AI), and autonomous systems. In this blog, we will explore the technical workings of 3D ToF sensors, their significance in various industries, and their potential in future technologies such as AI and image recognition.

How Do 3D Time-of-Flight Sensors Work?

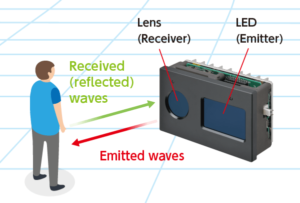

3D Time-of-Flight (ToF) sensors measure the distance to a target object by calculating the time taken for a light signal, typically in the form of infrared (IR) or laser, to travel to the object and return to the sensor. This process is known as light pulse reflection or time-of-flight measurement. There are two primary methods used in ToF technology: direct time-of-flight and indirect time-of-flight.

1. Direct Time-of-Flight:

In the direct ToF method, the sensor emits a modulated light signal (usually infrared) towards an object. The time it takes for the light to travel to the object and back is measured directly. This time is then converted into distance using the speed of light. This method is typically used in long-range ToF sensors due to its ability to cover large distances with high precision.

2. Indirect Time-of-Flight (Phase Shift Method):

The indirect ToF method is more commonly used in 3D imaging and depth sensing. The sensor emits modulated light at a specific frequency and measures the phase shift between the emitted and received light. By comparing the phase shift, the sensor can determine the distance to the object with high accuracy, even at shorter ranges. This approach is widely used in applications where high-resolution depth maps and 3D imaging are required, such as in robotics and autonomous vehicles.

Key Components of 3D ToF Sensors:

-

Light Source: Infrared LEDs or laser diodes are used to emit modulated light. For 3D imaging, laser light is often preferred due to its ability to focus tightly on small objects.

-

Detector: A photodiode or avalanche photodiode (APD) detects the reflected light. The detector measures the time it takes for the light to return to the sensor.

-

Signal Processing Unit: This is the core of the sensor, responsible for calculating the time-of-flight and converting it into distance data. The signal processing unit processes the phase shift or time delay and outputs a 3D depth map or point cloud.

-

Optics: Lenses or other optical components are used to focus the light on the target and direct the reflected light toward the detector.

Importance of 3D ToF Sensors in Industrial Applications

The industrial sector has adopted 3D ToF sensors in various applications due to their ability to provide accurate, real-time 3D data that enhances automation, monitoring, and decision-making. Some key industrial applications of ToF sensors include:

1. Robotics and Automation:

In industrial robotics, ToF sensors are used for obstacle detection, path planning, and collision avoidance. By providing precise depth information in real-time, robots can autonomously navigate environments, identify objects, and interact with them in a safe and efficient manner. For example, in a warehouse, autonomous robots can use ToF sensors to avoid obstacles, stack products, and perform inventory management tasks.

2. Quality Control and Inspection:

ToF sensors enable high-precision measurement and quality inspection in manufacturing. For example, in automotive production, these sensors are used to check the dimensions of parts, detect surface defects, and ensure proper alignment during assembly. The ability to measure at micrometer-level precision in real time ensures higher accuracy and reduces the need for manual inspection, thus improving productivity.

3. Machine Vision and Object Recognition:

In industrial settings, machine vision systems leverage ToF sensors to detect objects, evaluate their size and shape, and ensure they meet quality standards. This is crucial for industries such as electronics manufacturing, where minute details and complex shapes must be inspected to maintain high quality.

4. Security and Surveillance:

In industrial security, ToF sensors are used for intrusion detection and perimeter monitoring. By continuously scanning for movements and changes in the environment, they help detect unauthorized access or objects left behind in sensitive areas.

5. Augmented Reality (AR) and Virtual Reality (VR):

In industries like architecture and design, ToF sensors are being integrated into AR and VR systems for spatial mapping and 3D modeling. By providing real-time 3D data, ToF sensors enable more immersive and interactive experiences, improving design processes and client presentations.

The Future of 3D ToF Sensors in AI and Image Recognition

The future of 3D ToF sensors lies in their integration with AI and machine learning to enhance image recognition, object detection, and interaction in both industrial and consumer applications.

1. AI-Powered Object Detection and Recognition:

ToF sensors, when combined with AI algorithms, can provide advanced object recognition and gesture tracking. For example, in autonomous driving, AI algorithms can use depth data from ToF sensors to identify pedestrians, obstacles, and traffic signs, while AI models continuously improve the system’s ability to make decisions in complex environments. This integration makes ToF sensors indispensable in fields such as robotics, autonomous vehicles, and smart cities.

2. Human-Robot Interaction:

ToF sensors are enabling natural human-robot interaction (HRI) by tracking gestures, poses, and movements. By integrating machine learning models, robots can understand and respond to human actions, facilitating tasks like assembly, medical assistance, and customer service. As AI and ToF sensors evolve, this interaction will become more intuitive and seamless.

3. 3D Imaging and Facial Recognition:

In the realm of image recognition, ToF sensors can enhance facial recognition systems by providing accurate 3D face models. This helps in identifying individuals even in low-light or poor visibility conditions, making it suitable for security and authentication applications.

4. Enhancing Depth Data for AR/VR:

In AR and VR, depth data from ToF sensors is crucial for creating realistic and immersive environments. By integrating AI, these systems will become smarter, enabling real-time adjustments to virtual objects as users move or interact with them. This will improve gaming, training simulations, and product visualization.

Recent 3D ToF Sensor Modules:

Several companies have released advanced 3D ToF sensor modules, each offering different features and applications. Below are some of the most recent modules:

1. Omron B5L Series:

Omron’s B5L 3D ToF Sensor offers high-resolution depth sensing with a wide range of applications, including object detection and robotics. The B5L sensor uses infrared laser for high accuracy and can operate in diverse lighting conditions. It is designed for industrial automation, robotics, and other machine vision applications.

2. STMicroelectronics VL53L5CX:

STMicroelectronics offers the VL53L5CX, a long-range 3D ToF sensor that provides high-resolution depth data with a range of up to 4 meters. It supports a wide field of view and features multiple target detection capabilities, making it suitable for both consumer and industrial applications such as robotics and mobile devices.

3. Texas Instruments OPT8241:

The OPT8241 is a ToF depth sensor module from Texas Instruments that provides 3D data with a field of view of up to 120°. It is well-suited for applications in robotics, security, and industrial automation due to its fast depth measurement and wide field of view.

4. LeddarTech LeddarVu8:

The LeddarVu8 sensor from LeddarTech is a 3D ToF LiDAR sensor designed for high-performance applications such as autonomous vehicles, industrial automation, and smart cities. With 8 independent detection channels, the LeddarVu8 offers a 360° detection range and precise depth sensing.

Conclusion:

3D ToF sensors are revolutionizing a wide range of industries by providing real-time, accurate depth sensing and 3D imaging. Their applications in robotics, quality control, and autonomous systems are just the beginning. As AI and machine learning continue to advance, 3D ToF sensors will become even more integral in applications like object recognition, AR/VR, and human-robot interaction. With new modules being released regularly, the future of ToF technology looks promising, and it will undoubtedly play a key role in shaping the next generation of industrial and consumer technologies.