How Engineering, Physics, and Rule Interpretation Collided in Formula 1

Formula 1 has always been a battleground not only for drivers, but for engineers who live in the gray areas of the rulebook. Some of the most iconic moments in F1 history were born not from outright dominance, but from clever interpretations of regulations.

As Formula 1 prepares for the 2026 power unit regulations, a new technical controversy has emerged — one involving Mercedes and Red Bull Powertrains. At the center of it is a subtle but powerful engineering concept: thermal expansion and effective compression ratio.

This article breaks down:

- What the regulation says

- What Mercedes and Red Bull did differently

- The science behind the workaround

- Why it matters for the future of F1

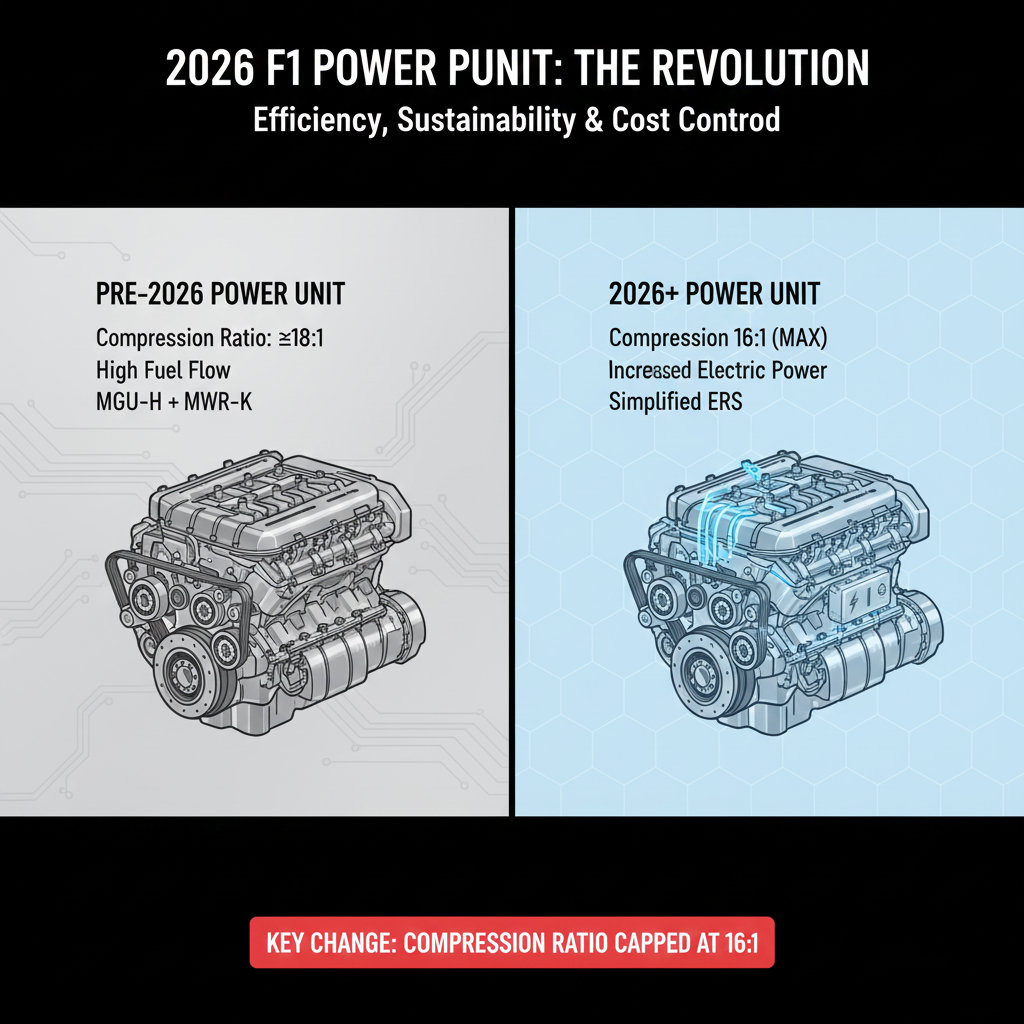

1. The 2026 F1 Power Unit Regulations — What Changed?

For 2026, Formula 1 is introducing a radically updated hybrid power unit aimed at efficiency, sustainability, and cost control. One of the key changes affects the internal combustion engine (ICE):

- Maximum compression ratio limited to 16:1

- Reduced fuel flow and increased reliance on electrical power

- Tighter definitions around engine architecture

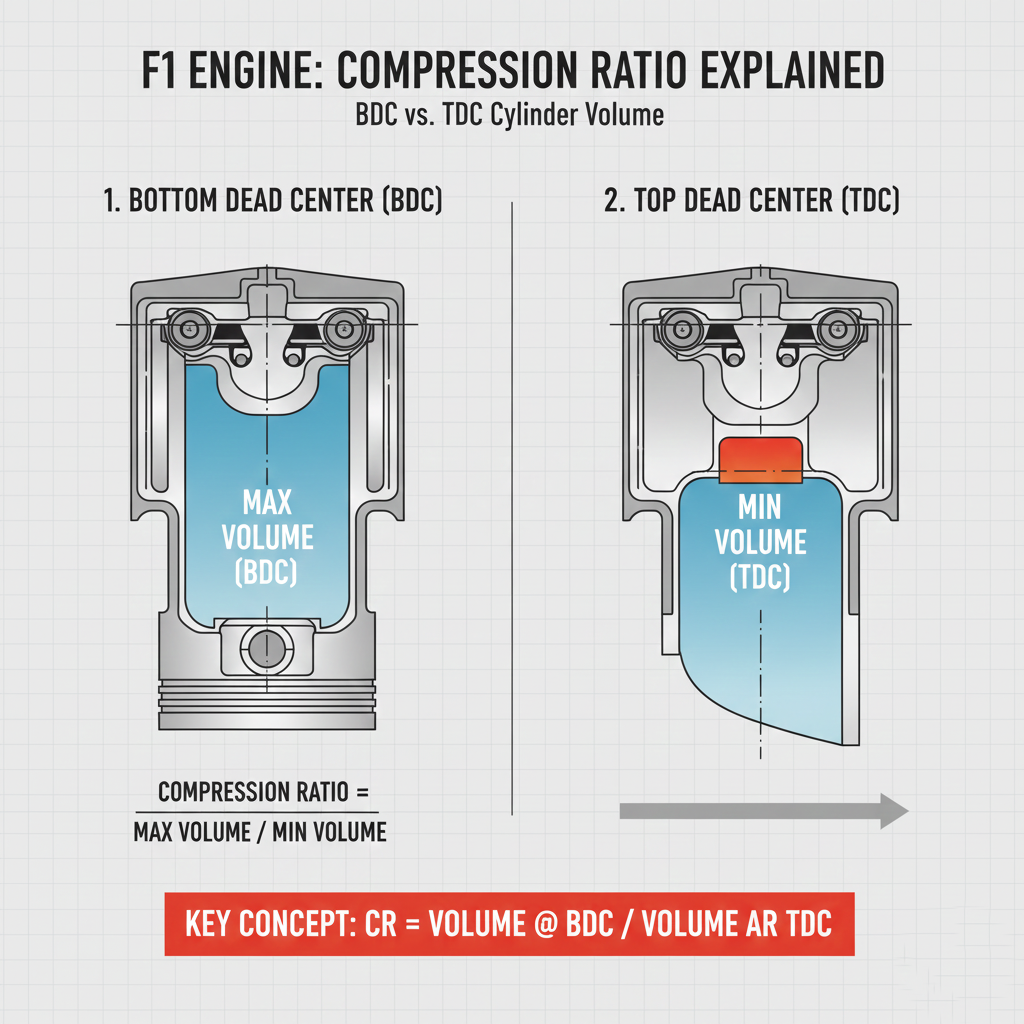

Why Compression Ratio Matters

Compression ratio is the ratio between:

- The cylinder volume when the piston is at bottom dead center (BDC)

- The volume when the piston is at top dead center (TDC)

Higher compression ratios generally mean:

- Higher thermal efficiency

- More power extracted from the same amount of fuel

- Higher combustion temperatures and pressures

By reducing the allowed compression ratio from previous eras (≈18:1), the FIA aimed to cap power and efficiency gains.

2. The Key Detail: How the FIA Measures Compression Ratio

Here’s where things become interesting.

The FIA technical regulations specify how compression ratio is verified, and this verification is done:

- At ambient temperature

- With the engine not running

- Using geometric measurements of cylinder volume

In other words, the compression ratio is checked when the engine is cold and static.

The regulations do not currently mandate:

- Measurement at operating temperature

- Measurement under dynamic combustion conditions

This creates a small but critical gap between static legality and dynamic reality.

3. The Workaround: Designing for Thermal Expansion

Mercedes and Red Bull are believed to have exploited this exact gap.

The Core Idea

All metals expand when heated — a fundamental law of physics known as thermal expansion.

The equation governing this behavior is:

ΔL = α · L₀ · ΔT

Where:

- ΔL is the change in length

- α is the material’s thermal expansion coefficient

- L₀ is the original dimension

- ΔT is the temperature change

Inside an F1 engine, temperatures can exceed 500–700°C in the combustion chamber.

What the Teams Likely Did

Instead of designing an engine that stays geometrically identical across temperatures, engineers:

- Selected materials with carefully chosen expansion coefficients

- Optimized piston crown shape, cylinder liner thickness, and head geometry

- Ensured the engine measures exactly 16:1 when cold

But once the engine reaches operating temperature:

- Combustion chamber volume slightly decreases

- Effective compression ratio increases

- The engine behaves closer to an 18:1 compression ratio under race conditions

All while remaining compliant during FIA inspection.

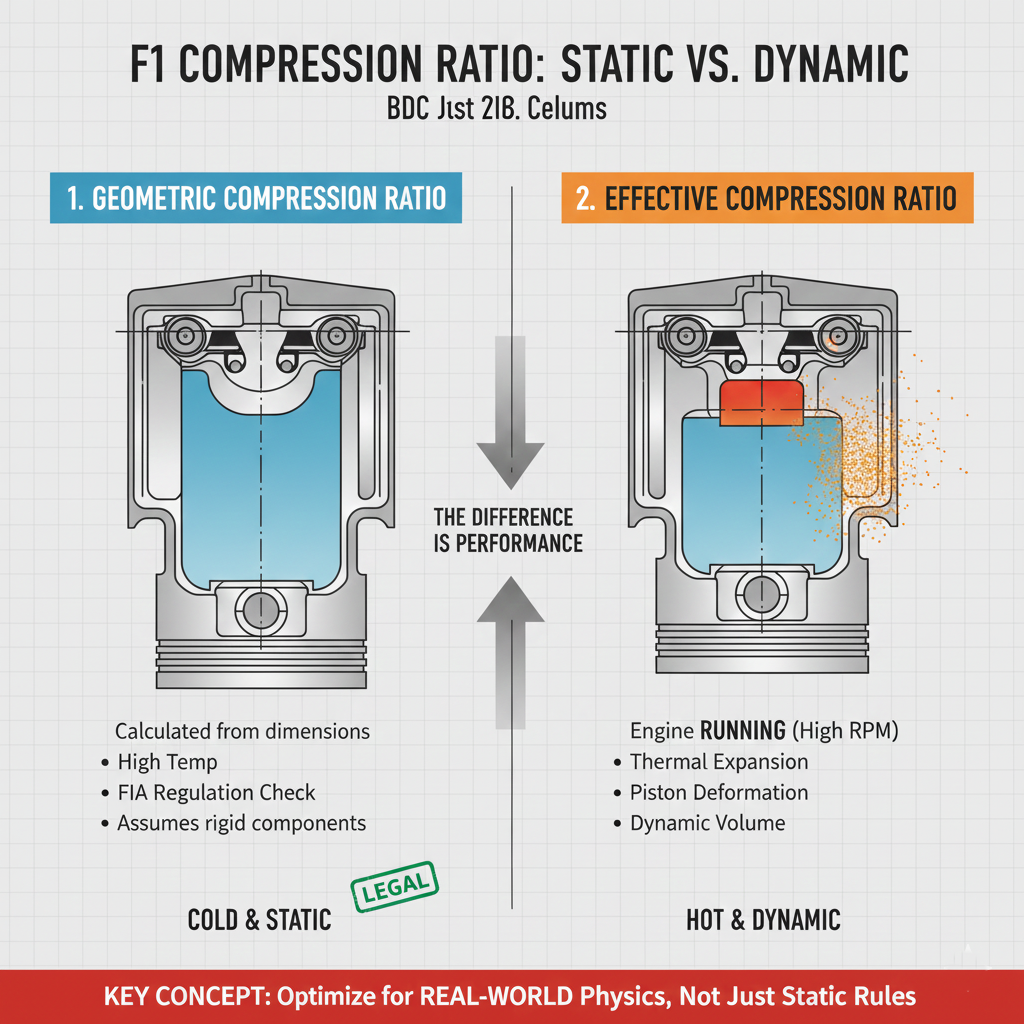

4. Effective vs Geometric Compression Ratio

This distinction is crucial.

Geometric Compression Ratio

- Calculated purely from physical dimensions

- Used by the FIA for regulation checks

- Assumes rigid, non-changing components

Effective Compression Ratio

- What the engine experiences while running

- Influenced by:

- Thermal expansion

- Combustion pressure

- Valve timing

- Piston deformation at high RPM

Mercedes and Red Bull appear to have optimized effective compression, not just geometric compression.

This is similar in philosophy to flexible aerodynamic parts that pass static tests but behave differently at speed.

5. Why This Produces a Performance Advantage

Even a small increase in compression ratio can yield:

- Higher peak cylinder pressure

- Faster flame propagation

- Improved fuel efficiency

- More power per combustion cycle

In F1 terms, this could mean:

- ~10–15 horsepower gain

- Several tenths of a second per lap

- A massive advantage early in a regulation cycle

In an era where margins are measured in milliseconds, this is decisive.

6. Why Other Teams Are Concerned

Manufacturers such as Ferrari, Audi, and Honda have reportedly raised concerns with the FIA, arguing that:

- Regulations state cars must be legal at all times

- The spirit of the rule was to limit real-world compression, not just cold measurements

- Allowing this sets a precedent for increasingly abstract interpretations

However, under the current wording, the designs remain technically legal.

7. FIA’s Position — Legal, For Now

The FIA has so far:

- Accepted the engines as compliant

- Acknowledged the interpretation gap

- Left open the possibility of future rule clarifications

Historically, this pattern is common in Formula 1:

- Engineers find a loophole

- FIA allows it initially

- Rules are rewritten or tests updated

Examples include:

- Blown diffusers

- DAS steering

- Flexible wings

- Dual-axis systems

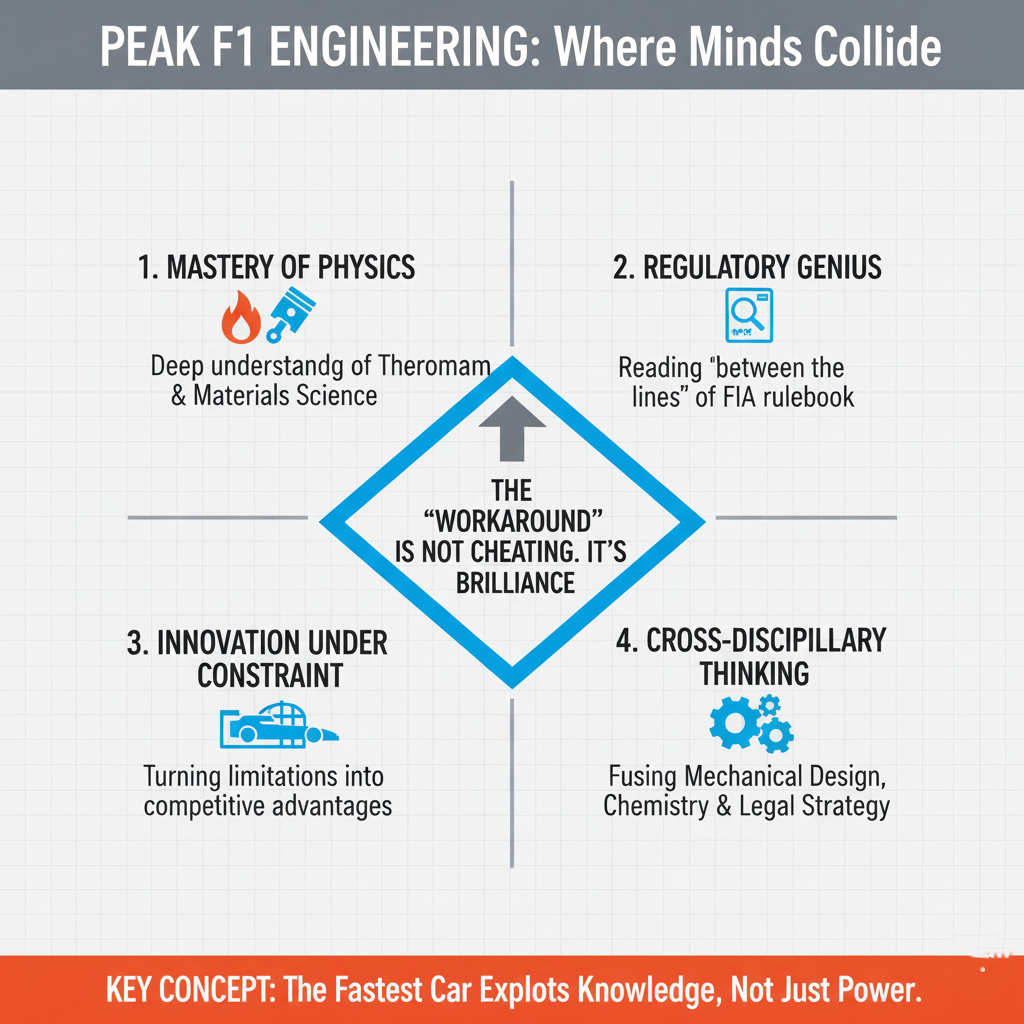

8. Why This Is Peak Formula 1 Engineering

This workaround is not cheating — it is engineering excellence within constraints.

It demonstrates:

- Deep understanding of materials science

- Thermodynamics applied at extreme conditions

- Mastery of regulatory language

Formula 1 has never been about following rules blindly — it’s about understanding what the rules actually say.

The Mercedes and Red Bull compression ratio workaround is a perfect example of how Formula 1 innovation evolves:

- The rulebook sets boundaries

- Engineers explore every molecule inside those boundaries

- The sport advances through tension between regulation and creativity

Whether the FIA closes this loophole or not, one thing is certain:

The fastest car is often built not just in the wind tunnel or on the dyno — but between the lines of the rulebook.

9. Why This Matters Beyond Formula 1

While this story unfolds at the highest level of motorsport, the underlying lessons extend far beyond Formula 1. In fact, the Mercedes and Red Bull workaround offers valuable insights for startups, R&D teams, and engineering-driven organizations in any industry.

1. Regulations Are Design Constraints — Not Design Killers

In many industries — energy, automotive, medical devices, telecom, fintech — regulations are often viewed as blockers. Formula 1 shows the opposite:

- Regulations define boundaries, not solutions

- Competitive advantage comes from designing within constraints, not avoiding them

- The best teams don’t ask “Why is this rule limiting us?” — they ask “What exactly does the rule measure?”

For startups, this means:

- Understand compliance requirements at a technical level

- Design products around how systems are validated, not just how they are described

2. Test Conditions Matter as Much as Real-World Conditions

One of the core lessons from this workaround is the difference between:

- Static testing vs dynamic operation

- Lab conditions vs real usage

Mercedes and Red Bull optimized performance where the engine actually operates, not just where it is inspected.

For R&D teams:

- Ask whether your validation tests reflect real operating conditions

- Look for performance gaps between “certified” and “in-use” behavior

- Simulate temperature, load, fatigue, and time — not just nominal values

3. Materials Science Is Often the Hidden Advantage

This workaround was not about software tricks or exotic algorithms — it was about materials behaving differently under extreme conditions.

Lessons for engineers:

- Material selection can be as powerful as architecture changes

- Thermal expansion, creep, fatigue, and phase behavior are often underutilized

- Small physical changes can unlock disproportionate system-level gains

Many industries underinvest in materials R&D because the gains appear incremental — until they aren’t.

4. Optimize the System, Not the Specification

A critical distinction highlighted by this case:

- Specifications define limits

- Systems define performance

Mercedes and Red Bull did not violate the compression ratio specification — they optimized the engine as a system.

For startups and R&D teams:

- Avoid optimizing individual parameters in isolation

- Focus on system-level behavior under real loads

- Look for emergent effects that appear only when components interact

5. Innovation Often Lives Between Disciplines

This solution sits at the intersection of:

- Thermodynamics

- Mechanical design

- Materials science

- Regulatory interpretation

Breakthroughs rarely come from one discipline alone.

For engineering leaders:

- Encourage cross-domain thinking

- Avoid siloed R&D teams

- Reward engineers who understand both physics and policy

6. The First Interpretation Advantage

In Formula 1, the biggest gains often come early — before rules are clarified or closed.

The same applies in business:

- Early movers benefit from ambiguity

- Late adopters must design for clarified (often tighter) rules

- Speed of interpretation is as important as speed of execution

This makes regulatory literacy a competitive asset, not an administrative task.

Final Thoughts

The Mercedes and Red Bull compression ratio workaround is more than an F1 story — it is a masterclass in applied engineering.

It reminds us that:

- Innovation thrives under constraints

- Performance gains don’t always come from obvious places

- The best engineers read specifications like lawyers and design like physicists

Whether you’re building race cars, hardware products, or deep-tech startups, the lesson is universal:

True competitive advantage is often found not by breaking the rules — but by understanding them better than anyone else.

Written for engineers, innovators, and R&D teams who believe progress happens where physics, creativity, and constraints collide.