LEO COMPUTERS

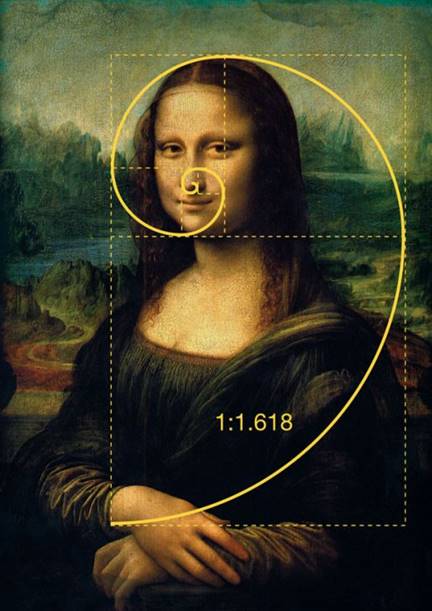

“LEO” the world’s first business computer you may not have heard of! https://www.youtube.com/watch?v=X0yYDxjBnTM The story behind leo computers The story starts back in the 1920s. J. Lyons & Co. were a family-run business established in the late 1800s to provide for important events such as the yearly Buckingham Palace garden party. It expanded fast, acquiring bakeries, ice cream, hotels, tea blending and packing, and the well-known teashops and Corner Houses. Keeping control of such a broad mix of enterprises required exceptional management. Lyons’ hired a young Cambridge graduate, John Simmons (who had graduated as a ‘wrangler’ – a first-class mathematician), as a management trainee and statistician in the early 1920s. His primary responsibility was to supervise improved methods of structuring company operations and management information. Simmons rapidly built a name for himself through a succession of inventions that changed several traditional methods. In 1932, he founded the Systems Research Office, which became a breeding ground for new methods. Following WWII, Simmons dispatched two of his junior managers, Oliver Standingford and Raymond Thompson, to evaluate office practices in the United States. They returned full of enthusiasm for electronic computers. The technology had recently been declassified by American authorities, and it was met with enthusiastic headlines about ‘electronic minds’ on both sides of the Atlantic. Thompson and Standingford had also discovered that Maurice Wilkes was creating a computer, the Electronic Delay Storage Automatic Calculator, at Cambridge University at the time (EDSAC). EDSAC’s electronics were thermionic valves (or vacuum tubes), and its memory was kept in mercury delay lines, which were mercury tubes that conveyed pulse trains in a more condensed form than copper wires. Simmons promptly established an agreement with Wilkes to provide £3000 as a fund to the project if Lyons could create a working replica. EDSAC was duly delivered, and in 1949, John Pinkerton, a Cambridge engineer hired by Lyons to lead the project, started working on LEO with a small team. Thompson began recruiting a team of programmers at the same time. David Caminer, Lyons‘ Head of Systems Research, created flowcharts of the sequence of instructions and information to be provided to the computer in an understandable fashion. To know more about the detailed story, we invite you to watch this video: https://www.youtube.com/watch?v=Zw0Vq35aIw0&t=3s LEO Computers Capabilities: In November 1951, LEO, which took up the entire floor of a big room, was ready to launch its first business program. It was named Bakery Valuations, and it calculated the costs of all the components used to make bread and cakes at the Lyons factory in Cadby Hall, west London. This is regarded as the world’s first routine, real-time office program. Soon after, LEO began to process payment for Lyons’ employees, and despite the machine’s inherent instability, a strict testing and maintenance schedule ensured that no one was ever paid late. The efficiency of the teashops was critical to the company’s profitability. Each customer spent a tiny amount, possibly a few pennies on a bun and a cup of tea. Because the transaction’s profit was so little, it was critical to reduce waste while increasing sales. Manageresses had to complete out documents in six different order books to resupply. Deliveries took more than a day to arrive at the stores, by which time their requirements may have altered. To increase efficiency, David Caminer created the Teashops Distribution role, which was implemented in 1953. He developed a standard order for each teashop based on its previous performance and implemented a daily telephone update to guarantee the orders were correct. Using the telephone was a brilliant idea, allowing for real-time, online connectivity long before the internet. LEO was also kept busy with contract work, such as computing missile trajectories for the Ministry of Defence and processing payroll for thousands of workers at Ford’s Dagenham plant. In 1954, the Lyons board of directors resolved to establish a subsidiary, Leo Computers Ltd, to build and sell computers. Only three versions were released! LEO I LEO II LEO III LEO II differed little from LEO I, except the last few were equipped with more compact magnetic core storage. In the early 1960s, Leo Computers used transistor technology for the first time, creating the LEO III, a cutting-edge machine. SOURCE: Meet leo, the world’s first business computer. Science Museum. (n.d.). Retrieved August 27, 2022, from https://www.sciencemuseum.org.uk/objects-and-stories/meet-leo-worlds-first-business-computer LEO COMPUTERS “LEO” the world’s first business computer you may not have heard of! https://www.youtube.com/watch?v=X0yYDxjBnTM… Europe is Gas-Thirsty in Winter! It is the most extreme energy crisis that has ever occurred in Europe as experts in global gas markets… How Is Rubber Made? WHAT IS RUBBER? Rubber is an elastic material made from petroleum, natural gas, or natural plant exudates… Natural Rubber Shortage: A Crisis at the Gates Natural rubber with all its chemical and physical properties is considered a main building block for… FIBONACCI SEQUENCE AND THE GOLDEN RATIO OF BEAUTY It is realized mathematically that everything in nature starting from the smallest atoms to the most… BlockChain What is BlockChain Technology? Blockchain technology is a sort of distributed ledger that offers a shared,… NASA: PICTURE OF THE DAY NASA’S WEBB DELIVERS DEEPEST INFRARED IMAGE OF UNIVERSE YET Picture of the day ! With the amazing declaration… No posts found 1 2 3 4 5 Follow US Facebook Twitter Youtube Instagram Linkedin